Overview

As the demand for vehicle electronics and data continues to grow, automakers are transitioning toward incorporating PCIe NVMe SSDs. These high-performance storage solutions are expected to be widely implemented in the coming years. Our latest automotive-grade PCIe NVMe SSD controllers, designed from the ground up with PCIe technology, provide top performance for each generation, low power consumption, and advanced error correction, making them ideal for automotive applications. These controllers also feature data path and EMI protection for enhanced reliability.

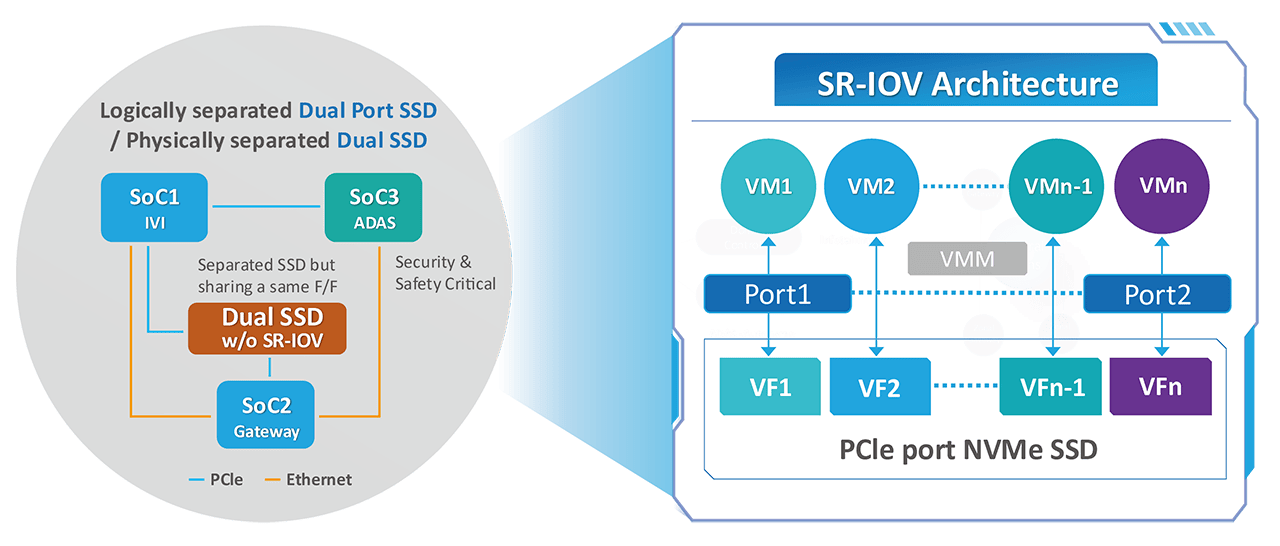

Using advance process technology for high throughput, lower power consumption, and rigorous data protection, our controllers provide ultra-high performance and reliability for automotive applications — including a cost-effective PCIe NVMe SSD solution for automotive storage. Ideal for automotive computing environments, we now offer controllers with built-in SR-IOV capability, consuming 30% less CPU power compared to PCIe Gen4 SSDs without SR-IOV. This high-speed PCIe interface supports up to eight virtual machines, fulfilling multiple requirements and functions for software-defined vehicles.

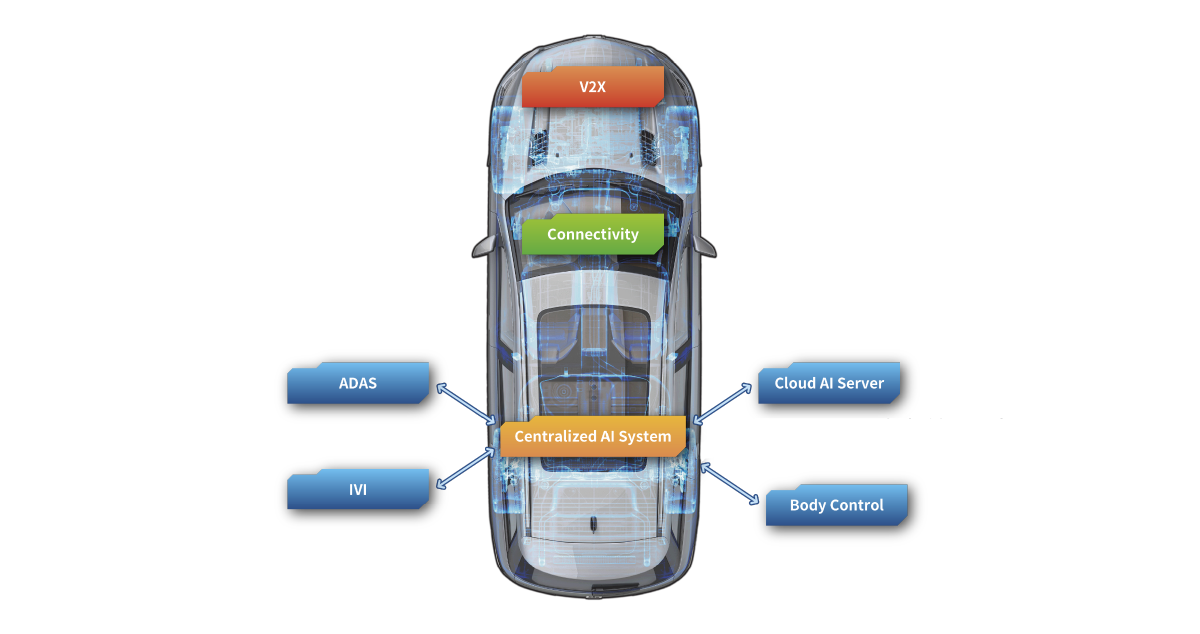

Driving the Future of Automotive Applications: Centralized Architecture

As smart vehicles become increasingly intelligent and user-focused, the role of this will be enabled by SDV (Software-Defined Vehicle) technology driven by centralized compute architecture in a car. This architecture enables a high-performance CPU to control all key vehicle functions, including ADAS, infotainment, safety, security, and energy management. In this scenario, AI plays a pivotal role in enhancing these functions, while high-performance SSDs enable the CPU to access and process data quickly, ensuring optimal performance across multiple applications.

A centralized architecture consolidates all electronic systems into a single, centrally managed platform, requiring a high-end transmission system and a variety of storage applications.

Implementing SR-IOV within this architecture offers greater software functionality, easier remote management, and high-speed, independent interfaces for each virtual machine via dedicated virtual functions. This capability is critical for supporting the complex, real-time data requirements of future vehicle architectures.

Here are the competitive advantages our SSD controllers provide for the automotive industry:

Data Path Protection

- End-to-end data path protection

- SRAM ECC for SRAM soft/hard errors

TSMC Automotive Service Package

- Tightened process control and scrap criteria

- Documentation and failure analysis

Extended Temperature and Voltage

- -40°C to +85°C (Grade 3)

- -40°C to +105°C (Grade 2)

- High-voltage SRAM test

Traceability

- OTP controller die stores unique ID to trace back wafer map or wafer lot

Silicon Motion's Contributions to the Automotive Industry

AECC

AEC-Q100 Grade 3/2

ISO 26262

ISO 21434

ASPICE certification

Supplier chain certification by IATF 16949

As a global leader in NAND flash controllers, we are dedicated to providing high-performance, reliable, and secure solutions that meet the automotive industry's stringent requirements. Our products undergo rigorous testing, including compliance with AEC-Q100 Grades 2/3, ISO 26262, ISO 21434, and IATF 16949 certifications. Additionally, Silicon Motion guarantees product supply longevity, reducing the need for costly requalification processes.

Products

SM2264XT-AT

A Game Changer in Automotive SSD Controllers

The world's first SSD controller specifically designed for automotive applications with support for Single Root I/O Virtualization (SR-IOV). This advanced controller supports up to eight virtual functions, significantly reducing the CPU's burden by efficiently managing multiple virtual machines that access the SSD simultaneously.

Features

High Data Integrity and Security

- Self-encrypting drive (SED) with AES 128/256 and TCG Opal

- Data retention extension with 7th generation NANDXtend®

Best-in-class low power consumption

- Supports flash devices operating at VCCQ 1.2V/1.8V

- Lowest power usage under 2mW

Built-in SR-IOV capability

- Supports to up to eight virtual machines

- Multiple namespaces and firmware slots

Full automotive qualification

- Compliance with AEC-Q100 Grades 2/3 and ASPICE

- Compliance with the ISO 9000/9001, 26262 functional safety and 21434 cyber security standards

Technologies

Built-in SR-IOV Capability for Automotive Storage

Sharing a storage resource across multiple ECUs at near native speed

The SR-IOV architecture applies the concept of virtualization. This provides the flexibility to run a VM on any supported hardware target and optimizes the usage of the available hardware resources. The ultimate result is reduced hardware costs: A data center that implements a virtualized system can perform more computing operations with fewer servers than an older, non-virtualized system.

The advantage of virtualized architecture is that data transfers no longer need to be routed via the hypervisor (virtual machine manager, or VMM), thus eliminating the delay caused by translating software code from PCIe format into hypervisor format and back again. This also reduces the burden on the CPU in which the hypervisor runs.

Silicon Motion's SSD controller offers built-in SR-IOV capability and supports up to eight VMs, which can interface directly at high speed — and independently — to each VM via a dedicated virtual function (VF) implemented in the SSD controller.

TSMC Advanced Process Technology

Our controllers' progressive architecture is based on advanced process technology, allowing for high throughput, lower power consumption, and uncompromising data protection combined with ultra-high performance and dependability in an economical PCIe NVMe SSD storage solution.

7th Generation NANDXtend ECC Technology

More Reliable, Efficient and Power-saving ECC technology for the latest and next-generation 3D NAND

NANDXtend® is an advanced firmware technology developed exclusively by Silicon Motion to meet the design requirements of SSDs with 3D NAND. Combined with LDPC (low-density parity check) and RAID data recovery correction technologies, the NANDXtend three-level error correction algorithm can decode in parallel and correct errors with precision and at high speed. Together, these technologies extend the P/E cycle performance of 3D NAND, prolonging the SSD's lifespan and ensuring data integrity.

End to End Data Path Protection

Silicon Motion's SSD controller solutions incorporate full data error detection with recovery engines to provide enhanced data integrity throughout the entire host-to-NAND-to-host data path. The data recovery algorithm can effectively detect any error in the SSD data path, including hardware (for example, ASIC) errors, firmware errors, and memory errors arising in SRAM, DRAM, or NAND.

Downloads

Blog

Selection Guide

| Filters |

|---|

| Filters |